Metal Components for Industrial Applications: What Buyers Should Expect from a Trusted Fabrication Partner

Metal components play a critical role in the performance, durability, and reliability of industrial equipment and systems. From structural supports to enclosures and assemblies, these parts are expected to perform under demanding conditions for years at a time. When failures occur, the consequences often include downtime, safety risks, or costly repairs. For industrial buyers, sourcing dependable metal components starts with choosing the right fabrication partner.

Washington Metal Fabricators is a full-service fabrication shop based in Washington, Missouri, supporting manufacturers across the United States and Canada. With a broad range of fabrication capabilities and a production-focused approach, WMF helps industrial customers source components that meet performance expectations and support long-term manufacturing needs.

Industries That Rely on High-Quality Metal Components

A wide range of industries depend on fabricated metal parts to keep operations running smoothly. While performance requirements vary by application, consistency and reliability are common expectations across sectors.

Manufacturing and industrial equipment rely on frames, supports, and housings that must maintain alignment and strength under continuous use. Electrical and transformer systems depend on precisely fabricated enclosures and structural elements that protect sensitive equipment. Medical and commercial equipment manufacturers require components that meet strict quality standards and perform reliably in controlled environments. Retail fixtures and structural applications also depend on durable fabricated parts that balance strength, appearance, and repeatability across production runs.

Across these industries, buyers expect metal components that integrate cleanly into larger systems and perform consistently over time.

Common Types of Industrial Fabricated Parts

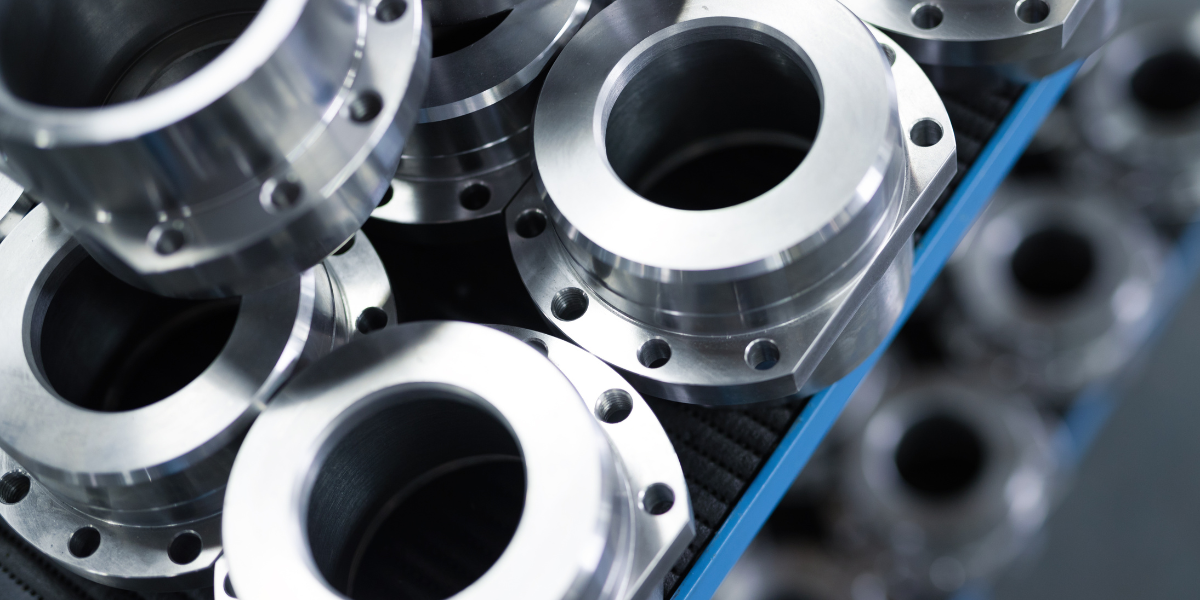

Industrial fabrication supports a wide variety of part types, each serving a specific function within a larger system. Washington Metal Fabricators produces a broad range of parts to meet diverse application needs.

Typical fabricated items include structural elements that provide strength and support, enclosures and housings designed to protect equipment, brackets and frames used to mount or connect systems, and welded or formed assemblies that combine multiple parts into a single functional unit. These items vary in size, complexity, and material, but all require accurate fabrication and consistent quality to perform as intended.

Understanding how these parts function in real-world applications helps ensure they are produced with the appropriate level of precision and durability.

Fabrication Capabilities That Support Industrial Production

Producing reliable industrial parts requires more than a single fabrication process. Washington Metal Fabricators offers a wide range of capabilities that support production from start to finish.

WMF’s fabrication services include laser cutting and CNC punching for precise flat parts, forming and stamping for components that require bends or complex shapes, and CNC machining for features that demand tighter tolerances. Welding services support both manual and robotic processes, providing strong, repeatable joints across assemblies. Finishing services such as grinding, polishing, and powder coating help protect parts and meet durability or appearance requirements. Assembly and warehousing capabilities further support customers who need coordinated production and inventory solutions.

These capabilities allow WMF to support industrial components at varying levels of complexity while maintaining consistency throughout fabrication.

Why Full-Service Fabrication Matters for Industrial Parts

Working with a full-service fabrication shop offers practical advantages for buyers sourcing industrial components. Managing multiple fabrication processes under one roof reduces handoffs and improves coordination between steps.

At Washington Metal Fabricators, full-service fabrication supports tighter process control, more predictable outcomes, and reduced variability across production runs. This approach is especially valuable for parts that must fit precisely with other components or perform reliably within larger assemblies. Fewer handoffs mean fewer opportunities for misalignment, inconsistent quality, or scheduling delays.

For industrial buyers, this results in smoother production flow and more dependable outcomes.

Quality Control Expectations for Industrial Fabrication

Quality control is essential to the performance and longevity of fabricated parts. Buyers should expect consistent inspection practices that verify components meet requirements before entering service.

Quality control practices at Washington Metal Fabricators include:

In-process quality checks during fabrication

Final inspection prior to shipment

Verification of critical dimensions and features

Consistent standards across repeat production runs

Strong quality control helps ensure metal components perform as expected, reducing the risk of rework, downtime, or premature failure. For industries that rely on long-term equipment performance, this oversight is critical.

Supporting Custom and Production Manufacturing Needs

Industrial projects often vary in scale. Some require one-off or low-volume fabrication, while others involve ongoing production programs. Washington Metal Fabricators supports both custom work and repeat production, allowing customers to scale without changing partners.

Maintaining continuity with a single fabrication partner helps preserve consistency as requirements evolve. Buyers benefit from working with a shop that understands their programs over time and can maintain quality standards as volumes increase. This continuity reduces variation and helps ensure reliable results throughout the life of a project.

Materials Used in Industrial Fabrication

Material selection has a direct impact on part performance and lifespan. Washington Metal Fabricators works with common industrial metals such as carbon steel, stainless steel, and aluminum, each chosen based on application requirements.

Carbon steel is often selected for strength and durability, stainless steel for corrosion resistance and clean environments, and aluminum for lightweight applications where strength-to-weight ratio is important. Consistent material handling and fabrication practices help ensure predictable performance across different environments and use cases.

Material knowledge plays a key role in producing reliable industrial parts.

Location, Logistics, and Production Support

Washington Metal Fabricators is located in Washington, Missouri, approximately 50 miles southwest of St. Louis. This central location allows WMF to support customers throughout the United States and Canada with efficient logistics and responsive communication.

Centrally located production reduces shipping complexity and supports reliable delivery schedules. Combined with full-service fabrication capabilities, this location allows WMF to coordinate production and distribution effectively for a wide range of industrial customers.

Choosing a Fabrication Partner for Industrial Components

Industrial buyers sourcing metal components need a fabrication partner that understands real-world production demands. Consistency, reliability, and quality all play a role in long-term performance and operational efficiency.

Washington Metal Fabricators supports industrial customers with full-service fabrication capabilities, disciplined quality control, and a production-focused approach. If you are evaluating fabrication partners for metal components used in industrial applications, you can contact our team today to discuss your needs, follow Washington Metal Fabricators on Facebook for updates and insights, or connect with their team on LinkedIn to learn more about their capabilities and experience.